Key Benefits

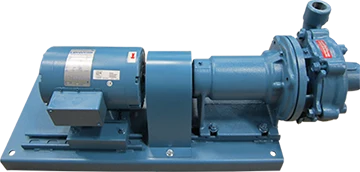

- Radically split casing for maximum hydraulic efficiency and pull design eliminates need to disturb piping.

- Drain and vent tapping’s are provided.

- The impellers are designed for smooth performance and maximize efficiency. Each is dynamically balanced for quiet vibration free operation and extended bearing life.

- Precision machined adapters assures perfect alignment between motor and casing. A seal vent/flush tapping is also provided.

Oversized re-grease able style bearing with long life rating. - Heavy duty slide rail steel base for simplified shaft alignment.

- Our mechanical seals prevent leaking with standard seals good up to 250°F at 175 psi. Optional seals can go up to 400° F.

- The shaft sleeve design assures a dry motor shaft and easy troubleshooting if necessary.

- Shafts for 56J motors are threaded SS and JM frame motors have keyed carbon steel shafts.

- T-frame motors with heavy duty grease lubricated ball bearings.

MEPCO Pumps are a result of years of development. We have worked with engineers, contractors and customers in the Hydronic Heating, Air Conditioning and Refrigeration Industries. In addition our engineers have followed the Hydraulic Institute Standards.The present-day MEPCO, drawing from the experience of its predecessor companies, has the combined experience of that heritage and has evolved over the years from stuffing box water seals to mechanical seals and from ball bearings that required lubrication to sealed bearing that require little to no maintenance.

Our pumps are used in many applications such as general industry, HVAC, booster service, chilled and hot water circulation, cooling towers, irrigation, boiler feeds, process fluids, washer service, water supply, condensers, spray systems, water transfers to name some. We also provide them for OEM and private label applications.